Ø Introduction

The article is related to what is the slab? And what are the different

types of slab in construction? Slab is the important component of structure.

The Slab provides roof to the structure which provide comfort to user.

Ø What

Is The Slab?

· The Slab is the horizontal structural member which is used

to form floors, roof decks and ceilings.

· It is made up

of concrete or reinforced cement concrete.

· The slab is working as roof when placed at the top of the structure, the roof or the slab is supported by columns, beams and walls.

· Usually, reinforced concrete slab and beam cast monolithically in the structure.

Ø Different Types of Concrete Slabs in Construction

There are different types of concrete slab which are used in

construction. Some are outdated and some are used nowadays. We are discussing

in detail as follows,

1. Flat Slab

2. Flat Plates

3. Conventional Slab

I. One Way Slab

II. Two Way Slab

4. Hallow Core Slab

5. Hardy Slab

6. Dome Slab

7. Pitch Roof Slab

8. Slab With Arches

9. Post Tension Slab

10. Pre-Tension Slab

11. Cable Suspension Slab

12. Low Roof Slab

13. Projected Slab

14. Grad Slab / Slab On Grad

I. Slab On Ground

II. Stiffened Raft

Slab

III. Waffle Raft

Slab

15. Bubble Deck Slab

16. Composite Slab

17. Sunken Slab

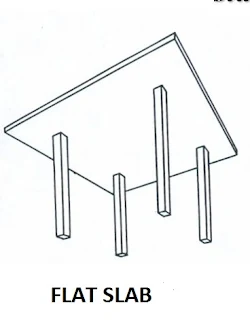

1.

Flat Slab

· Flat Slab is the simplest type of slab use in construction of

slab, in which slab is constructed on column or column cap without the use of

beam.

· This slab is

easy to construct it is economical because it requires less form-work.

· Due to absence

of beam the slab also called as beam less plate.

· The thickness

of slab is than other type of slab.

· The floor to

floor height is minimized by the slab construction, which makes structure’s

view pleasant.

· The flat slab

specially used at the location where no need of beam for making pleasant look

of structure such as restaurant, hall, business houses, parking deck, etc.

2.

Flat Plates

· The Flat

Plates can be constructed as one-way as well as two ways.

· The slab is

supported by walls and columns.

· The flat

plates are easy to construct, and they need less or simple form-work.

· The

construction process of the flat is very fast.

3.

Conventional Slab

· The Conventional

Slab is placed on beams and columns.

· The thickness

of the conventional slab is small i.e. 4” or 10 cm.

· In conventional

slab beam and column carry and transferred load to the foundation so the depth

of beam is large.

· The

conventional slabs require more form-work as compare to flat slab.

· The

conventional slab consist of reinforcement, the bars which are placed horizontal

in slab is called main reinforcement bars and the bars which are placed

vertical in slab is called distribution bars.

· According to

length and width of the conventional slab, it again divided into two types as

follows,

I. One Way Slab

II. Two Way Slab

I. One Way Slab

· One Way Slabs carry load along one direction which is supported

by beam on two opposite sides.

· The condition

for one way slab is the ratio of longer span to shorter span of slab should be equal

to and greater than 2.

· The main bars

are placed along the shorter direction, and distribution bars are placed along

longer direction and they are cranked to resist formation of stresses in slab.

II. Two-Way Slab

· Two-Way Slabs carry load along both direction and is supported by

beams on all four sides.

· The condition

for two-way slab is the ratio of longer span to shorter span of slab should be

less than 2.

· The Distribution

bars are provided in both directions, so the bars are cranked in both

directions.

· The two-way slab requires more form-work.

· The slab is used for multistory buildings.

4. Hallow Core Slab

· Hallow

Core Slab is the precast slab with cores or voids.

· The slabs

require less concrete so the self weight of the slab is less.

· The voids or cores act like service ducts,

like plumbing and electricity.

· The slab is

caste where the fast constructions are required.

· With reducing

the weight of structure, it reduces the cost of structure.

· It is suitable

for car parking, multistory buildings, etc.

5. Hardy Slab

· Hardy Slabs are made up from hardy bricks of size 40cm x 20cm x 20cm, which are hallow bricks consist of hollow concrete blocks. The use of hallow bricks reduce the self weight of slabs.

· The thickness of the hardy slab is 270mm which is greater than the conventional slab

· The construction of the hardy slab is suitable at such locations like Dubai, China, etc. where temperature is higher because they are good heat insulators.

6. Dome Slab

· Dome Slab is built on the conventional slab which is semi-circular in shape and mostly used in temples, palace, mosques, etc.

Thickness of the slab is 150 mm, which is a concrete slab.

7. Pitch Roof Slab

· The Pitch

Roof is constructed for aesthetics view to look pleasant and natural.

· They are

inclined slabs, in which tiles sheets are used as roofing material which are

lightweight.

8. Slab With Arches

· The Slab

with Arches are mostly constructed at bridges.

· They were

constructed by stone or bricks, but nowadays they are constructed by reinforced

concrete or steel.

· For

redirecting wind loads the arch slab is adopted.

9. Post Tension Slab

· The Post

Tension Slab is tensioned after constructing a slab.

· To resist compression

in slab, reinforcement is provided but in post tension slab cables or steel

tendons are used.

· Post tension slab provide better structures with affordable price.

10.

Pre-Tension Slab

·

The Pre-Tension Slab is tensioned before placing the slab.

· In this slabs cables or steel tendons are used in spite of reinforcement.

11.

Cable Suspension Slab

· The Cable

Suspension Slab is used where the span of slab is very longer and difficult

to build columns, then such pan is supported by the cables. For examples Howrah

bridge, London bridge, etc.

· At every 500 m

distance, a column is provided.

· The slabs are

tied with the cables and these cables are joined to the columns.

12.

Low Roof Slab

· Low Roof Slab is provided above the door for storage purpose.

· This slab is

used specially in houses which are in between the actual slab and above the

door sill level.

· The slab is

open at one end and closed at all ends.

13.

Projected Slab

· The Projected

Slab is fixed at one side and free at other sides.

· Projected slab

also called s cantilever slab.

· The projected

slab is mostly constructed at hotels, function halls, etc.

· The space

below the projected slab is used for dropping or picking up zone and as loading

or unloading area.

14. Grade Slab / Slab On Grade

The slab which is constructed on ground is called

grad slab or slab on grad. It is again divided into three types as follows,

I. Slab On Ground

II. Stiffened Raft

Slab

III. Waffle Raft Slab

I. Slab On Ground

· The slab is

constructed on ground surface with stiffing beams which are constructed around

the perimeter of slab.

· The slab is only suitable at the ground surface with sand and rock. The thickness of slab is 100 mm.

II. Stiffened Raft Slab

· The Stiffened Raft Slab is like slab on ground or ground slab but difference is that beams are set through the middle of slab in the channels.

III. Waffle Raft Slab

·The Waffle Raft Slab is constructed above the ground by using

polystyrene blocks.

· First of all polystyrene blocks are placed on ground and then concrete is poured on the surface.

· If the ground is very flat then the waffle raft slab is the choice, which is easy to construct and cheaper also. .

15. Bubble Deck Slab

· For the construction of Bubble Deck Slab prefabricated plastic

bubbles are used at the place of ineffective concrete at the center of slab.

· The plastic bubbles are

prefabricated and then reinforcement placed. Lastly concrete is poured over the

plastic bubbles.

· Bubble deck slab reduce the

self weight of slab and increase strength.

· It reduces the cost of

construction and it is environmental friendly.

·

16. Composite Slab

· The composite slab is the

combination of reinforced slab and steel decking means the reinforced concrete

cast on top of the profiled steel decking.

· During construction period

steel decking act as form-work and working area, and in service life

of slab, it acts as external reinforcement.

· The slab is made up of

concrete to reduce floor’s deflections and vibrations. Also concrete is fire resistive.

17. Sunken Slab

· The Sunken Slab is the slab

which is provided below the washrooms to hide sewerage pipes or sewage pipes.

· The pipes which carry water are hidden below the floor. The flooris filled with coal or broken pieces of bricks, after casting the pipes.

· There are two types of sunken slab as follows,

o The slab which provide above normal floor level t height of

0.2m to 0.3m and the space is filled

with the coal and broken pieces of bricks.

o The slab which provide below normal floor level t height of

0.2m to 0.3m and the space is filled

with the coal and broken pieces of bricks.

No comments:

Post a Comment